radial turbo compressor for water as refrigerant

Post by Arda Rahardja Lukitobudi @ Grup FB IKARA

Untuk artikel PDF Turbo Water Chiller with Water as Refrigerant

Purdue University

Purdue e-Pubs International Compressor Engineering

Conference School of Mechanical Engineering

2004

Turbo Water Chiller with Water as Refrigerant

Eberhard Wobst

Institut fur Luft-und Kaltetechnik

Nikolai Kalitzin

Institut fur Luft-und Kaltetechnik

Rainer Apley

Institut fur Luft-und Kaltetechnik

TURBO WATER CHILLER WITH WATER AS REFRIGERANT

Eberhard WOBST, Nikolai KALITZIN, Rainer APLEY

Institut für Luft- und Kältetechnik gGmbH, Main Department of Refrigeration & Cryogenics,

Dresden, Germany

(++49-351-4081-630, ++49-351-4081-635, eberhard.wobst@ ilkdresden .de)

ABSTRACT

The use of natural refrigerants in energy efficient refrigerating plants becomes more and more important for the

protection of the environment against air pollution e.g. by HFCs and CO 2 . The ILK Dresden is dealing with the

development of turbo water chillers with water as refrigerant. The design of such chillers has to be tailor-made

because of the thermodynamic properties of water. The paper describes the present situation in this ILK working

field. On basis of first experiences with running of these chillers at car manufacturers like DaimlerChrysler or VW

the ILK Dresden will continue its R&D activities in this field.

1. INTRODUCTION

The worldwide restrictions for the use of CFCs and HFCs caused by the proved environmental pollution due to

ozone depletion and greenhouse effect call for the search for environment-friendly refrigerants. The natural

refrigerants like water (R718), air, carbon dioxide (R744), ammonia (R717) and propane (R290) are some of them.

The research and development activities for the use of water as refrigerant for compression refrigerating systems

were started in the Dresden Institut für Luft- und Kältetechnik (ILK Dresden) in 1991. The research resulted in the

two-stage turbo chillers with intercooling. Since 2000 the first of them have been proved in practice.

2. PROPERTIES OF WATER AS REFRIGERANT

The advantages of water as refrigerant are above all its non-limited availability, its low price compared to other

refrigerants, its simple handling and its non-toxicity. Disadvantages are especially the low specific cooling capacity

which results in high volume flows, pressure levels below ambient pressure and high pressure ratios. The

comparison of the most important properties of water and ammonia is shown in Table 1.

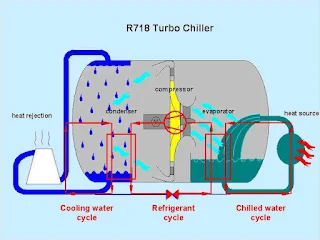

3. DESIGN AND FUNCTION OF R718 TURBO CHILLERS

Design and function of the chiller are influenced by the thermodynamic and physical properties of the refrigerant

water. The high pressure ratio requires two-stage systems.

The cold water is expanded to the evaporation pressure at the evaporator inlet distributor and partially evaporated in

this direct heat-exchanger. The evaporation heat which is drawn from the cold water leads to a cool down of the

water. The water vapour is then compressed to a mean pressure in the first stage compressor. Superheated vapour

is cooled down to nearly the saturation temperature by a partial evaporation of water through the direct contact with

water. The water vapour is compressed to condensing pressure by the second stage compressor. The condensation

is also realized by the direct contact of water vapour and cooling water. Because the evaporation and the

condensing pressure are in the range of vacuum it is normally recommended to separate the chiller from outer water

networks (cooling and cold water) by plate-heat-exchangers. Figure 3 shows the design scheme of the two-stage

refrigerating system with all its main components and water as refrigerant. The two radial turbo compressors are the

core of the R718 turbo chiller.

On this basis ILK Dresden developed a type series of R718 turbo chillers for a cooling capacity range of 500 to

1,000 kW. The typical cold water outlet temperatures are between 4 and 10°C. COPs of 4.6 to 7.75 are reached

depending on the load conditions and water temperatures.

Design of an R718 turbo chiller

4. RADIAL TURBO COMPRESSOR

The radial turbo compressor for water as refrigerant is the main component of these chillers. The design of this

compressor is influenced decisively by pressure ratio, volume flow and the medium water vapour. The obtainable

pressure ratio is proportional to the impeller diameter and the square of speed. The volume flow also depends on the

speed, the impeller diameter and the blade and channel width, respectively. The largest compressor of this type,

developed by ILK Dresden, has an impeller diameter of 1.20 m, speed up to 9,200 rpm and generates a cooling

capacity of 1,000 kW for the range of air-conditioning. The pressure ratio amounts to about 2.5 per stage and the

volume flow to about 50 m 3 /s.

The design of the compressor is shown in Figure 4. The intake nozzle with the entry vanes minimizes incidence

losses at the impeller inlet. The impeller transfers kinetic energy to the fluid. Two tandem-arranged diffuser vanes

and the following vane-less diffuser decelerate the flow, increasing the static pressure.

The medium water vapour demands and enables the application of very thin and very lightweight carbon fibre

reinforced impeller blades. But these extremely lightweight blades produce themselves a centrifugal force per

double-blade of 15 kN. On the other side the density of water vapour is this low at the low evaporation

temperatures of 4 to 10°C that the fluid forces are negligible compared to the centrifugal forces. The blades are flat

and therefore they are loaded only along their radial fibres.

Compressor design scheme

%20Desember%202022%20(10).jpeg)

KOMENTAR