Evaporative cooling, otherwise known as adiabatic cooling, works on the principle of water evaporation through which the air is cooled down to a comfo

History of evaporative cooling

Since the early days of human civilization, evaporative cooling has been used to cool down living environments. Egyptian murals have been found, dating as far back as the year 2500 BC, that depict how porous clay vessels filled with water were placed beneath an air inlet to provide some cooling when the air passed through them. They could not have made use of electric fans or other modern techniques, but elements of evaporative cooling were implemented in the design and architecture of their housing, to provide a form of climate control. Besides that, evaporative cooling using wet rags in combination with a wind tower (wind catcher) is a traditional Iranian architectural element to provide cooling in buildings.

Evaporative cooling system: how does it work

In an evaporative cooling system, hot outside air is forced through wet cooling pads by means of a motor-driven fan. The cooling pads are moistened continuously by a water pump that delivers water to the cooling pads. The cooled down air is then blown into the building. The outcoming air can then be cooled down between 60 and 90 % of the wet-bulb depending on the effectiveness of the evaporative media. The outcoming air is cooled down 10 to 15 °C but contains a high amount of humidity. Therefore direct evaporative cooling is not recommended for cooling in work and living environments.

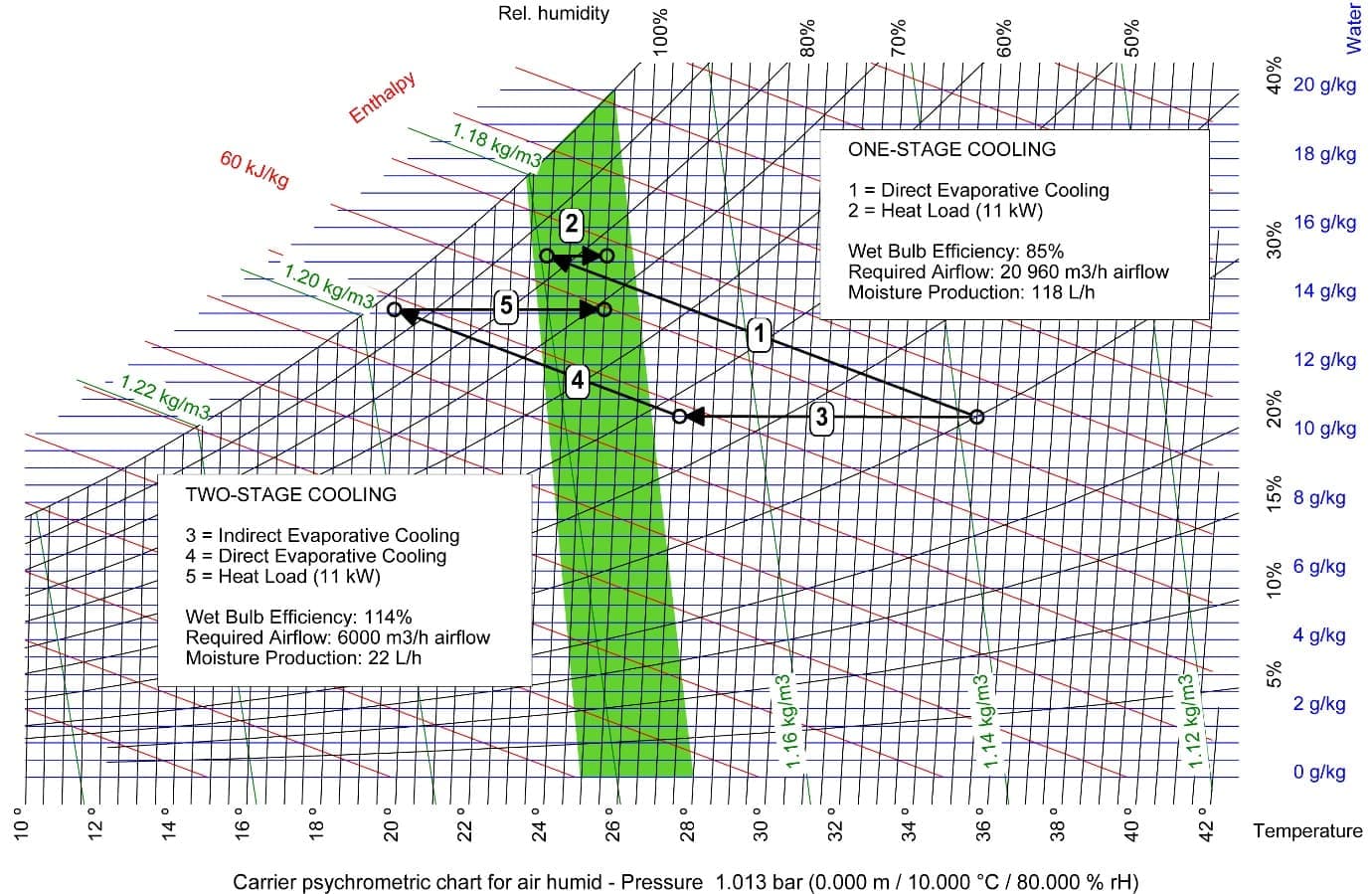

Two-stage evaporative cooling, on the other hand, produces efficiencies up to 114% of the wet bulb, resulting in temperatures up to 7 °C lower, and due to the lower temperature, it contains 60% less humidity than direct evaporative cooling processes.

The graphic shows an example of a one-stage evaporative cooling process vs a two-stage evaporative cooling process with outdoor air at 35 °C and 30% relative humidity. We can see that a one-stage evaporative cooling process produces indoor air with a higher humidity content than a two-stage evaporative cooling process (~80% vs ~69%). Furthermore, the wet-bulb efficiency of a one-stage evaporative cooling process is lower than a two-stage evaporative cooling process (85% vs 114%). Finally, the required airflow to achieve the same indoor temperature of 25 °C at the same heat load (11 kW) is more than 3 times higher in case of a one-stage evaporative cooling process (20 960 m3 /h vs 6000 m3 /h). This implies that the moisture production of a one-stage evaporative cooling process is more than 5 times higher (118 L/h vs 22 L/h).

How does evaporative cooling work?

Evaporative cooling, otherwise known as adiabatic cooling, works on the principle of water evaporation through which the air is cooled down to a comfortable temperature.

It is a cooling and ventilation technique that uses water as its refrigerant.

During the evaporative cooling process, water is evaporated in a stream of air and passes from a liquid to a gas. This transition requires energy, which is extracted from the air in the form of heat. As a result of this process, the air is cooled down.

This evaporative cooling process can be applied in several ways:

- Direct adiabatic cooling

- Indirect/direct adiabatic cooling

- Indirect adiabatic cooling

For a clear overview of what these different methods entail, check out our page about ‘two stage evaporative cooling’.

%20Desember%202022%20(10).jpeg)

KOMENTAR