Reduced power consumption up to 30%. The technology is based on the heating capability of air during compression and cooling down during expansion.

The air cycle is widely used in air separation plants as a cooling stage to obtain cryogenic cold, to liquify natural gas, as well as in aircraft air conditioning systems. And we use the air cycle in the production of refrigeration machines. The heart of the system is turbo-module unit developed and manufactured in-house for the most efficient and reliable work.

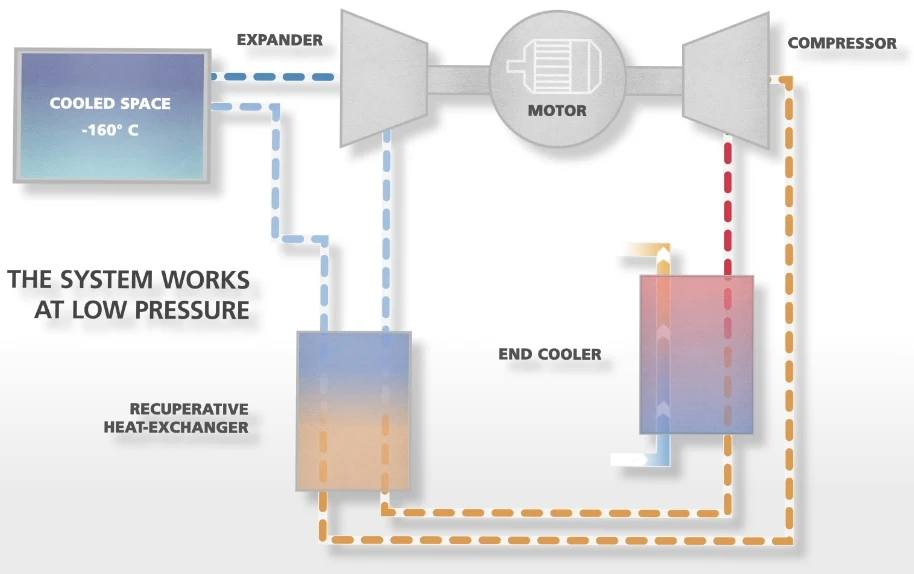

The technology is based on the heating capability of air during compression and cooling down during expansion. Repetition of compression and expansion cycles allows to reach and maintain ultra-low temperatures down to -160°C.

The key feature is the location of turbo expander and compressor are on the same shaft. The energy generated in the expansion process is transferred through the shaft to the compressor, thereby reducing energy consumption by up to 30% compared to vapor compression systems.

Product review for MIRAI

%20Desember%202022%20(10).jpeg)

KOMENTAR